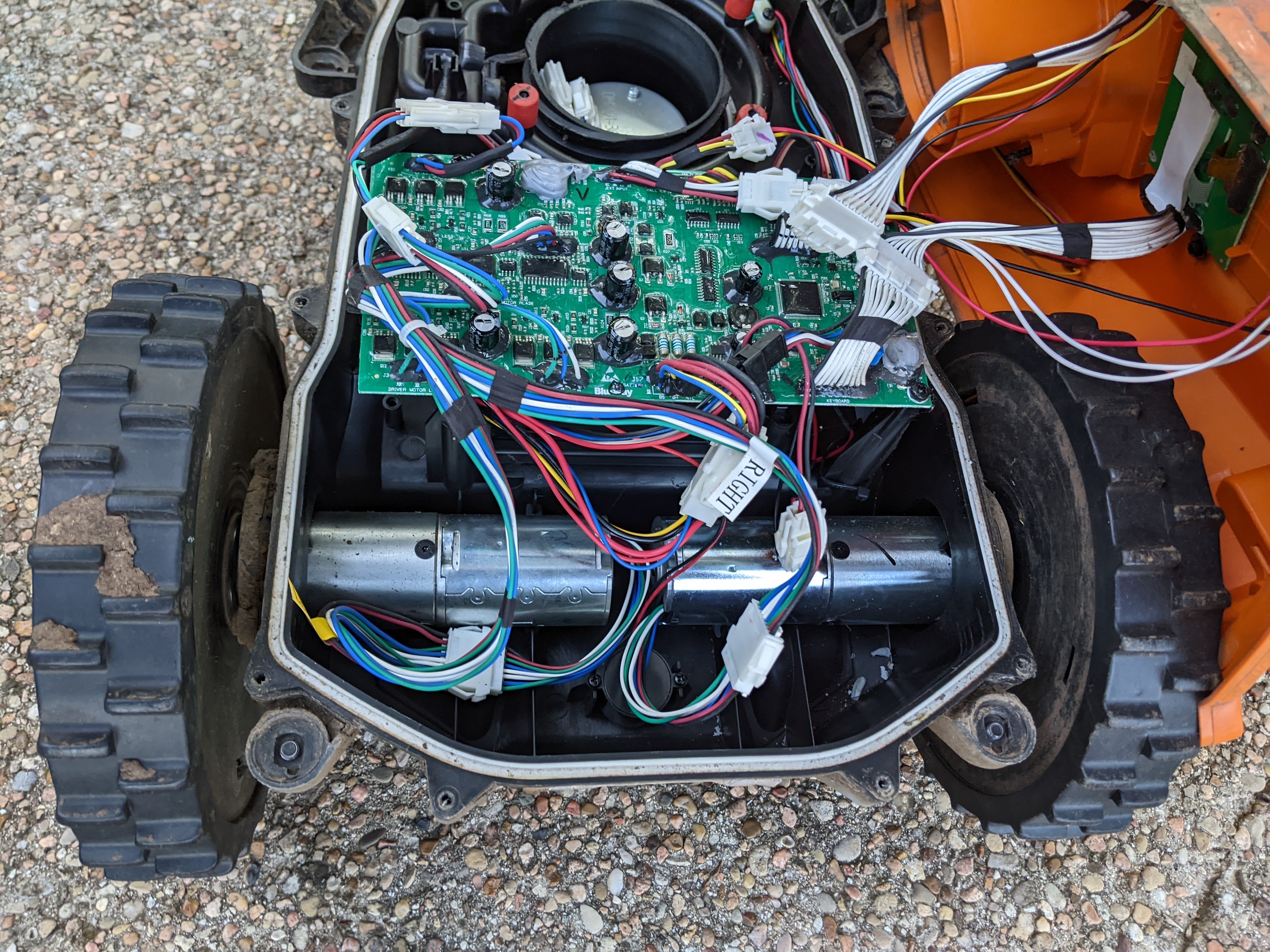

I re-asembled the Landroid, having swapped the rusty old “lifted” sensor magnet for a new neodymium magnets I found on Amazon. They were too small by half, but two gave the exact 12mm x 12mm x 3mm size. These new magnets were significantly stronger, but figured it was worth a try. I saw three possibilities. It could with work just like the old magnet, or not work at all (never giving a lifted error) or it would work too well, always giving a lifted error, making the mower inoperable. I figured I has a 2 out of 3 chance. But I lost. After the mower was re-assembled, it was stuck with a “lifted up” error that wouldn’t clear. I cleaned up the old rusty magnet, replaced it, and it works, and seems to be doing better, so far not giving any errors.

Having a functional mower makes me less interested in hacking in a Raspberry Pi. But only a little less. I might switch focus and make a new boundary wire. I was going to try and build a circuit to drive a boundary wire at 70 Hz or so. Thought about using an audio circuit or even a small amplifier and “pretend” the wire loop is a speaker. There are also all sorts of modules out there like this $9 Sine wave generator that would probably work well. A little fancier and maybe worth it is this $26 signal generator. Not sure how strong the output is for driving the loop. I supose there is an amplifier module out there that would do the job if I needed more oomph. Might buy the nicer signal generator and play around with a small loop and see if I can keep my mower corralled. Then I could start making zones in other parts of the yard.