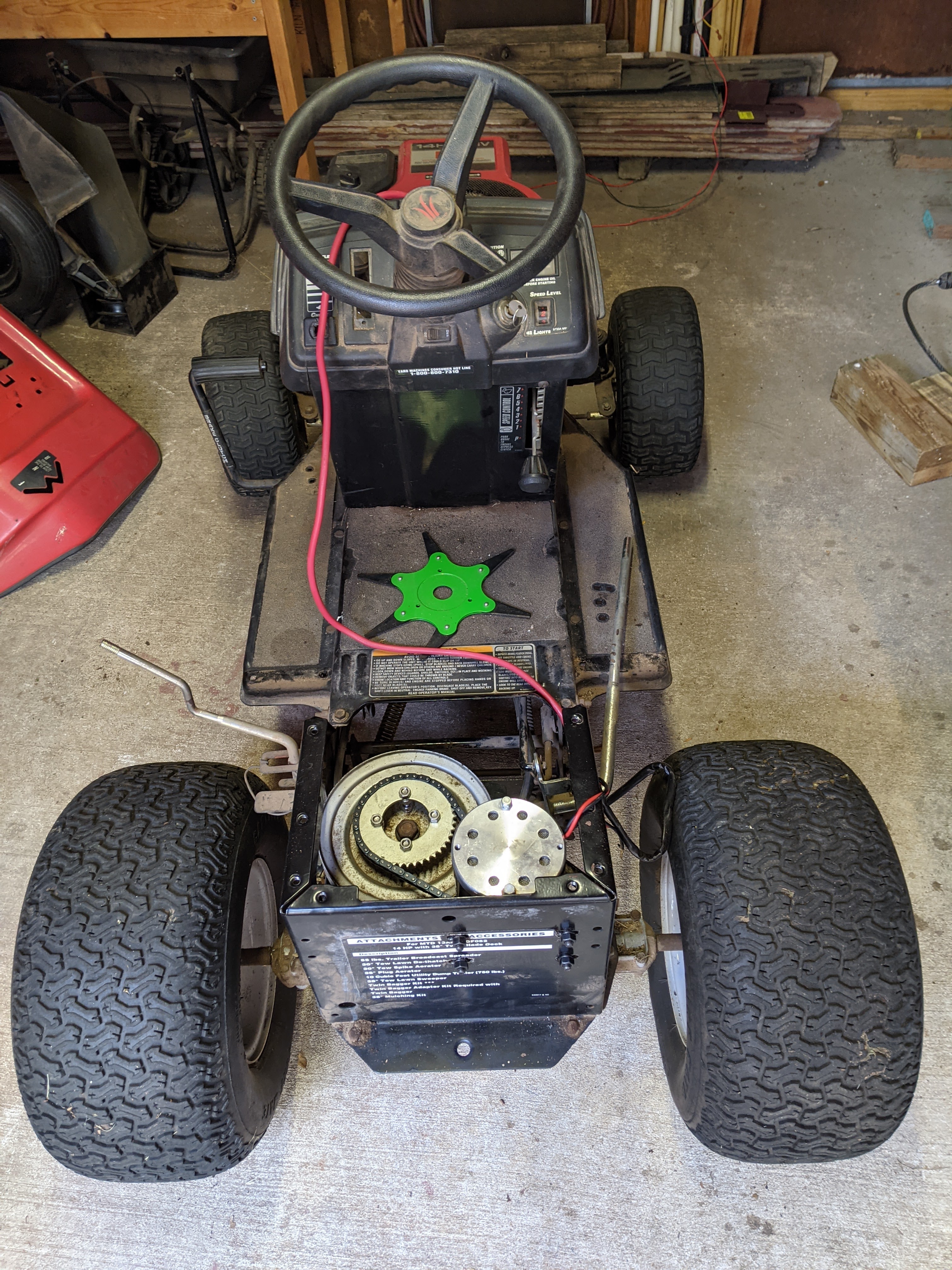

The good news is that I have ridden the riding mower. It occurs to me that I have put a motor where the battery was and batteries where the motor was. If that is progress. I’m taking a bit of a (holiday) break to regroup a bit. Some notes:

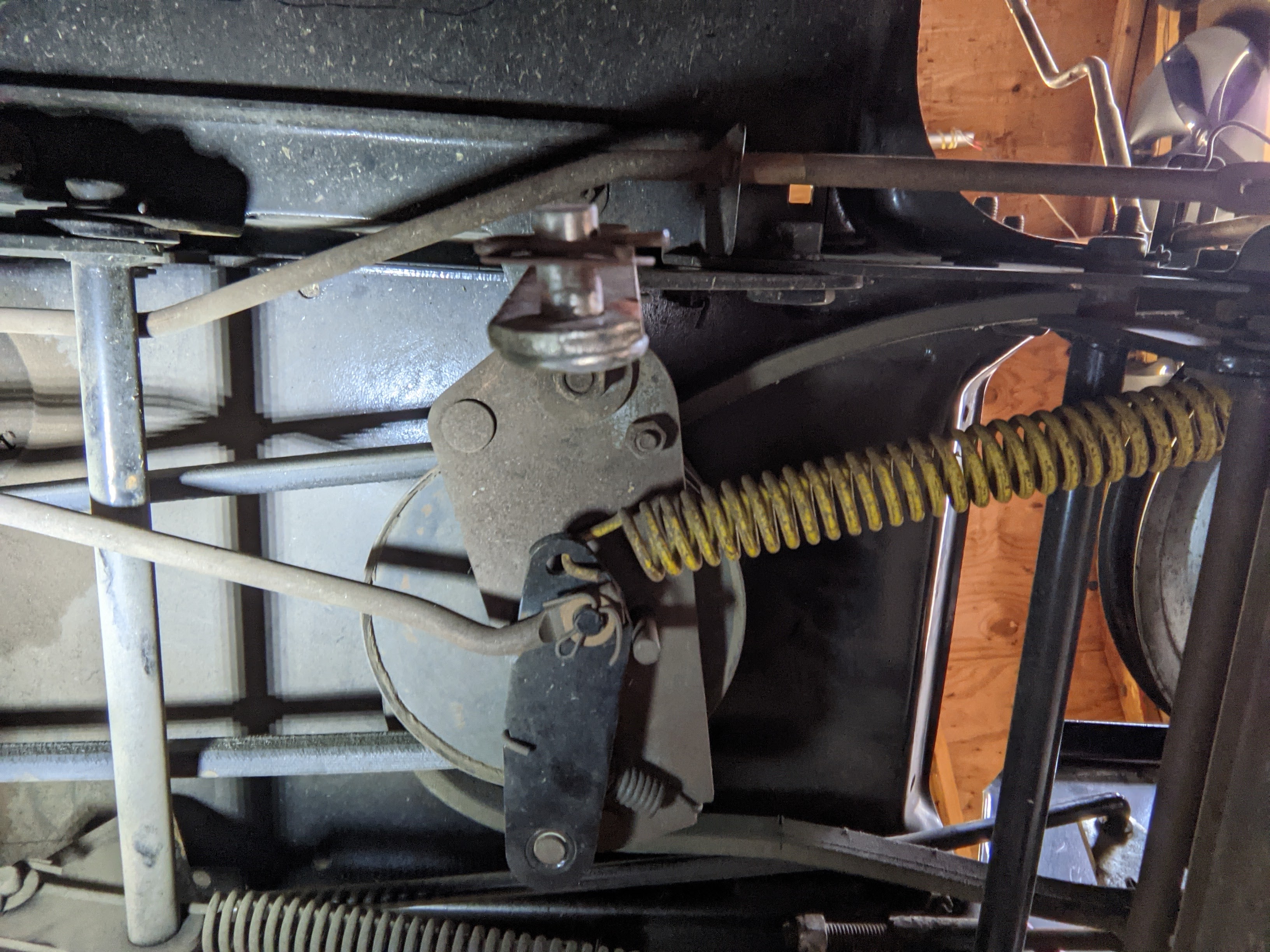

Speed: it is slower than I would like. I used a large gear for convenience which also has the effect of slowing things down. I have ordered a smaller gear that would speed things up. In no real hurry to change this. I can even eventually revisit direct drive with a shaft coupler.

Power: the original mower had a 14 horsepower engine. That would be a very large electric motor (at about 750 Watts per horse). I figured half that for general efficiency and half for moving the blades. Still a hefty motor. I was looking at a 1800W motor but eventually just went with the 500W based on gut. 500W turns out to be enough power for this vehicle, at least for my purposes. In the short test drive, power was never an issue, and the motor wasn’t even warm when I was done. Anyway, it looks pretty easy to swap out a motor if I want to upgrade.

Batteries: I went with the battery I had, a 12V lawn tractor starter battery. Not in any way ideal. I bought a second to get 24V. They are cheap and seem to be adequate. I can always change these. The new lithium batteries are light and hold lots of charge, but are expensive and don’t necessarily have a high output. This has led me to looking at chargers for battery banks and perhaps using the mower batteries as backup power, perhaps with solar charging. That seems like another project, though.

Electronics: Bought some new parts for control (variable resistor, switch, LED displays). Going to make a prettier display for the controllers. Ordered a second identical controller for the eventual blade motors. Also bought some proper wire and connectors (right now I’m using bits from the old mower which are not the correct sizes).

Blades: I have some ideas for the blades. That will be the second half of this project.

These projects aren’t much like the engineering projects I did professionally for years. I’m not constrained by a schedule or (within sane limits) costs. In that sense they are more Art Projects. I will mess around with them until I like what I have. There isn’t necessarily an endpoint deliverable. It is all for enjoyment.