I was starting to get a bit bored with the mower project. After all, the exciting part was actually getting it to go. But as I said, this isn’t about just basic functionality. So I’m adding a few bits.

First, a word about safety. The original mower had a few safety features. I don’t think I will replicate some of them. For instance you could not mow in reverse. I don’t know why, but the engine would stall if you tried. I assume it was safety related. I’m not concerned about this sort of thing. One safety feature was a switch on the seat that meant you had to be sitting on the seat for the mower to go forward. Probably a good idea. Don’t want unmanned riding mowers plowing through the neighborhood. Especially with an experimental vehicle like this, I am concerned about this issue. I was thinking of ways to use the existing seat switch, but it would mean running some wires places that I didn’t really want to run wires.

A few nights ago I had a thought. Jet skis have a little wrist strap that is attached to a kill switch. I could use something like that. Found one on Amazon. My wife also tells me the treadmills at gyms have similar switches, but I can’t imagine what these are for. Have a nice spot on the dash and I think this is my solution. Should be able to wire it into the forward / reverse / neutral switch.

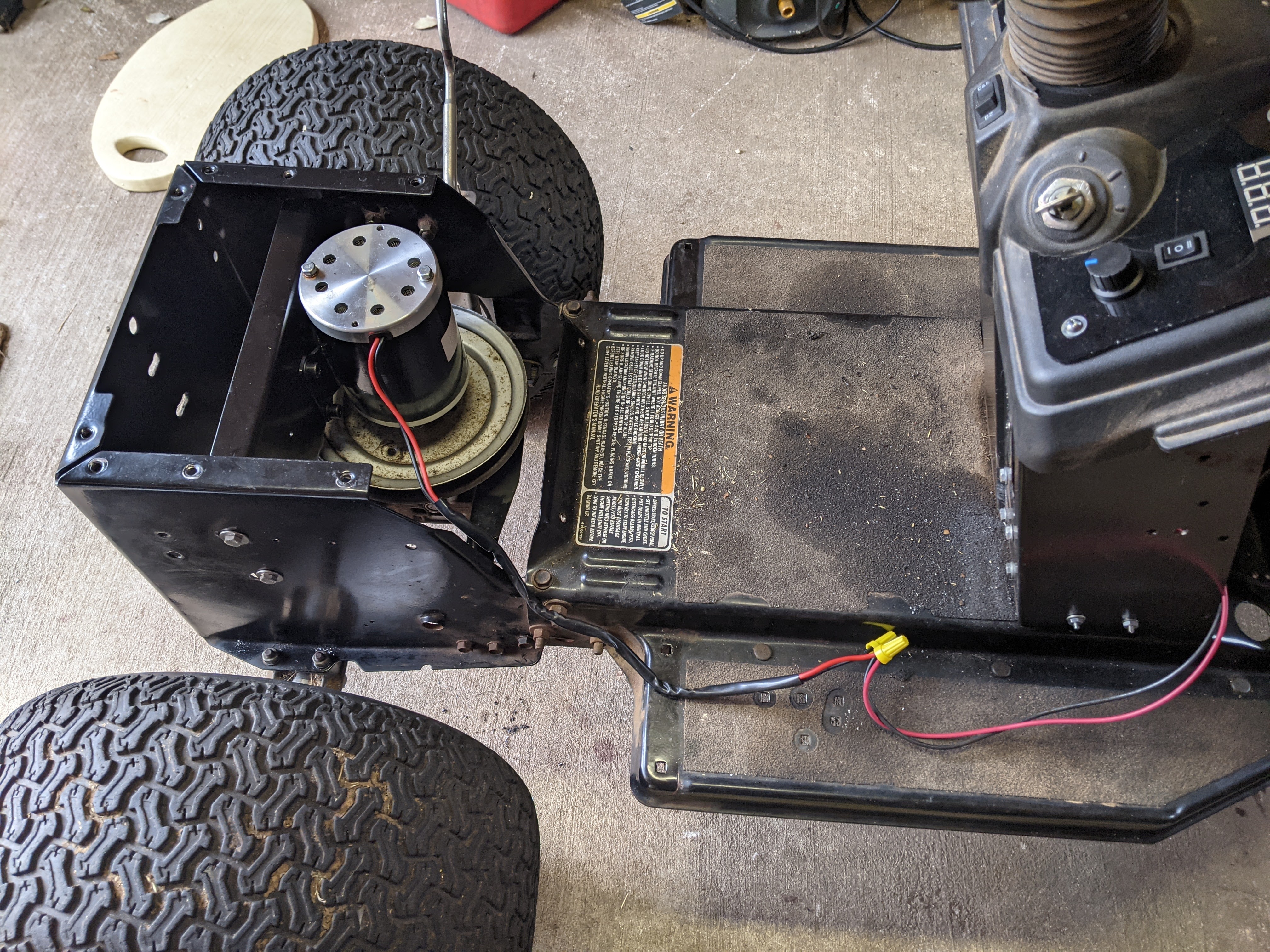

Also had some thoughts about charging. Right now the plan is to use a little 12V trickle charger one each battery as necessary. A bit clunky. I see Amazon has a smart 12V / 24V charger that would be nice. Tried it out and it seems to do the job. For now I’ll just use the clips, but installing a port is an option.

On the blades: today I’m thinking four blades on one piece of 2″ PVC pipe. Put them as close as possible and then offset it a few degrees so that there is some overlap when mowing (so there isn’t a stripe of unmowed grass between the blades). I need to think about mounting and controls. The deck up / down mechanism is pretty heavy duty and probably overkill. Probably time to buy the motors, blades and PVC pipe.

Oh, found a site that makes an adapter that I ought to be able to use for direct drive, eliminating the chain drive. Should make it very fast (maybe too fast). Not high on my list but will probably eventually try direct drive out. I figure I can always go back to the chain drive.